Stand-Up Rider vs. Sit-Down Electric Forklifts

Using the correct piece of equipment can actually have a major impact on the safety of your workplace. This guide will help show you the pros and cons of stand-up riders or sit-down electric forklifts and point you in the right direction for your next purchase, lease, or rental decision.

Factors to Consider When Buying a Stand-Up Rider or Sit-Down Forklift

On/Off Frequency

One of the main reasons you would consider using a stand-up rider is the fact that getting on and off the forklift can be considerably faster. With lower step heights and no seatbelt to take on and off, time spent entering and exiting can be cut down significantly. This is ideal for applications where operators are frequently getting off of the forklift throughout the course of their shift for activities such as picking product. The time and labor cost savings can really add up over time, depending on the frequency of operators’ getting on and off of the forklift.

Performance

Sit-down forklifts can have higher travel speeds and lift/lower speeds than stand-up riders, which can increase productivity and throughput in high volume applications.

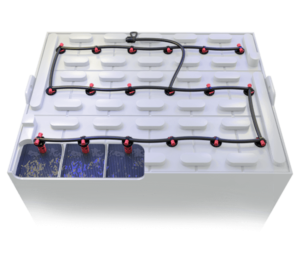

Additionally, Toyota’s sit-down forklifts come equipped with lithium-ion batteries that offer consistent power and battery voltage throughout the full charge, further increasing your operation’s efficiency.

Lifting Capacity

Stand-Up Rider and sit-down forklifts are both counterbalanced type forklifts. When comparing a stand-up rider to a 3-Wheel Electric Forklift with the same base capacity, you typically get more lifting capacity from the stand-up rider at higher lift heights due to the compact design and centralized center of gravity. Four-wheel electric models, however, typically attain the highest lifting capacities overall.

Purchase Price

The initial cost is typically higher for Stand-Up Rider Forklifts when compared to 3-Wheel Electric models.

Right Angle Stack

In general, right angle stacking capabilities are fairly similar between 3-wheel electric and stand-up rider models with similar capacities. Stand-up rider forklifts, however, usually have a small advantage due to their shorter length and can operate in slightly smaller aisles. Both stand-up rider and 3-wheel electric forklifts have a significant advantage over 4-wheel electrics in regard to minimum aisle width requirements.

Operator Preference

Operator preference tends to play a large role in most purchasing decisions for new equipment. Operators who are used to operating sit-down forklifts are generally resistant to swapping their sit-down for a stand-up rider and vice versa. The main reasons for this are the differences in operating position and operability. Stand-up riders are typically controlled by a single multi-function control handle while sit-down forklifts use conventional cowl-mounted levers or mini-levers. Sit-down forklifts also have traditional brake pedals, while stand-up riders use “plugging” (requesting travel in the opposite direction) for braking and have a dead man pedal for emergency braking. Being familiar with a particular operating style promotes safety and can help to increase productivity and operator confidence. But over time, operators tend to adjust and get used to the new controls and nuances.

Share this Post

Other Post

Toyota’s Moving Mast Reach Trucks: A Versatile Warehouse Solution